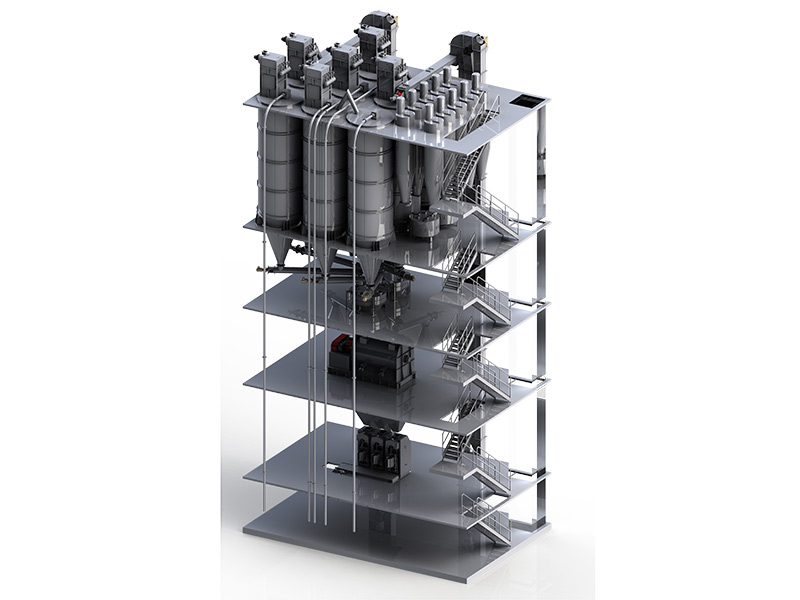

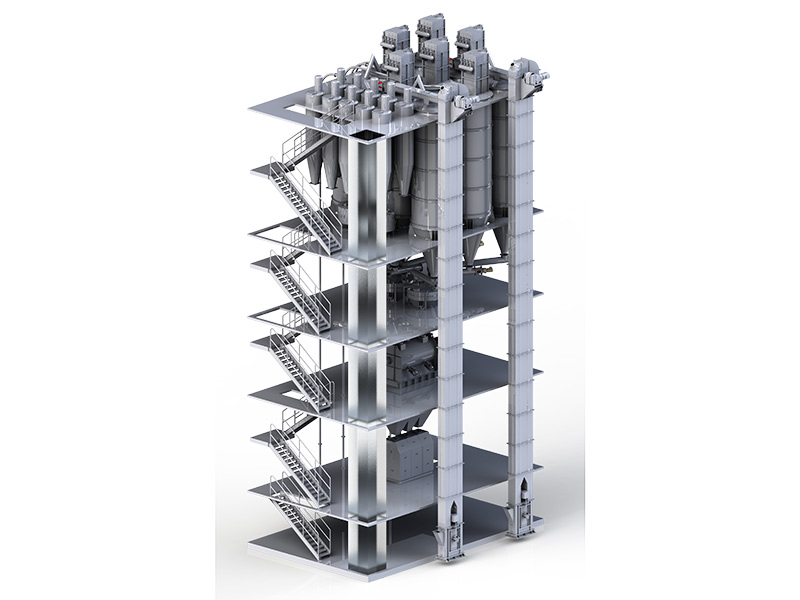

Dry mix plants, according to the desired capacity and mixing design can be designed in various types. Gypsum-based and cement-based dry mix systems are developing and rising day by day. The materials and chemical additives are most important design parameters determines the number of silos and bunkers in the system on the other hand the capacity of the system is directly depends on number of mixers and sizes. The final product obtained by mixing by mixers is packaged by linear or rotary packaging system. If asked the packaged products are then to be routed directly loaded into trucks by truck loading system or to palletizer. The capacity of the plants can be designed as 5 t/h to 50 t/h hourly capacity range as desired, it can be made double or more lines for higher capacities. In this case of gypsum-based products coarse and fine material processes can be mixed in separate lines. For cement based products gray cement and white cement products can be mixed in different lines.

| CAPACITY | LINE | CAPACITY | LINES |

| 5 tph | • |

40 tph | •• |

| 10 tph | • |

60 tph | •• |

| 15 tph | • |

80 tph | •• |

| 20 tph | • |

100 tph | •• |

| 30 tph | • |

120 tph | ••• |

| 50 tph | • |

150 tph | ••• |