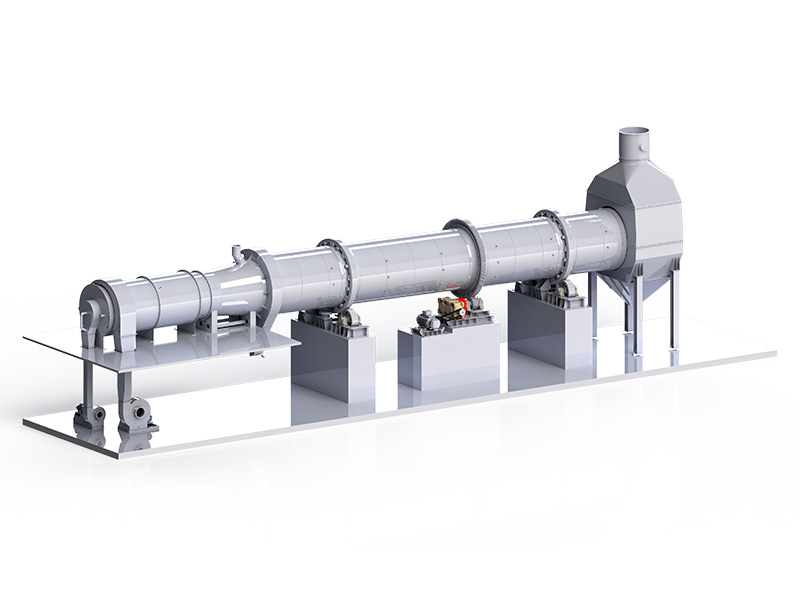

Rotary kilns are similar to cement kilns, but the main difference is the reverse flow of gypsum. Gypsum plaster is exposed at 600-650°C temperature during feeding in the kiln, at the end of the kiln it occurs around 150-160°C.

Calcination; after crushing process gypsum size is reduced to 0-8 mm. Sized gypsum feeds the kiln regularly by weighing belt. Gypsum moves through to the kiln depending on inclination and rotation of the kiln then calcined products come out. To reduce size of the calcined grains is transferred to grinding and classification steps.

5 t/h to 33 t/h in the range of our production capacities are available. The system is designed with two or more furnaces for higher capacities.

Gypmak is rotary kiln manufacturer for more information please contact with us.

| No | Type | Diameter mm |

Section Area m2 |

Power KW |

Capacity Tph |

Capacity Ton/day |

| 1 | GRK16 | 1.600 | 2,0 | 22 | 4.20 | 100 |

| 2 | GRK18 | 1.800 | 2,5 | 37 | 6.25 | 150 |

| 3 | GRK20 | 2.000 | 3,1 | 45 | 7.5 | 180 |

| 4 | GRK22 | 2.200 | 3,8 | 55 | 10.4 | 250 |

| 5 | GRK24 | 2.400 | 4,5 | 75 | 16.6 | 400 |

| 6 | GRK26 | 2.600 | 5,3 | 90 | 20 | 480 |

| 7 | GRK28 | 2.800 | 6,2 | 110 | 25 | 800 |

| 8 | GRK30 | 3.000 | 7,1 | 1600 | 33 | 800 |